Building & Environmental

Ensuring Reliable Environments

Control Your World

Your facility is the foundational element of your company's operational strategy, and controlling the physical environment is job one. A Building Automation System (BAS) monitors and manages all your facility's systems — electrical, HVAC, lighting, security, and more — to create and maintain a safe and productive environment. Implementing a BAS provides tangible benefits, including:

- Increased energy efficiency

- Higher productivity

- Data-driven decision making

- Increased safety and security

- Automated, centralized control

- Reduced maintenance, downtime

All Your Control Systems in One Place

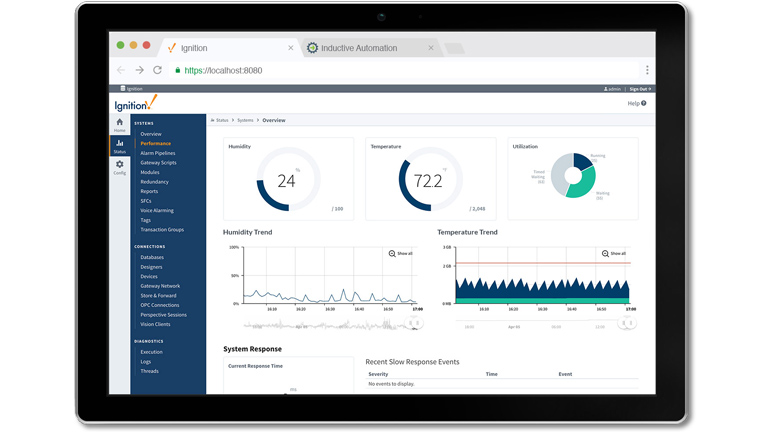

We integrate your separate control systems to create a comprehensive BAS, giving you the power to monitor and maintain your manufacturing conditions from one screen. Key features include:

Monitoring and Alarms

Monitor key envrionmental conditions such as temperature, humidity, pressure, vibration, and other metrics, to ensure that your environment is safe and compliant and machinery is operating at maximum efficiency.

Data-Driven Maintenance

Transform equipment data into actionable insights, to implement data-driven maintenance schedules that extend the lifespan of your equipment and optimize efficiency and reliability.

Improve with Analytics

Extensive data collection allows for in-depth analysis. This leads to more effective strategies, whether in resource allocation, maintenance scheduling, or process optimization.

Easier Compliance

By integrating multiple systems, BAS automates the process of tracking and reporting against regulatory standards, simplifying what can often be a complex and time-consuming aspect of operations.

Significant Experience in PLC-Based BAS

We have implemented industrial BAS control systems for some of the world's most demanding end users — including life-sciences facilities that require validated solutions and facilities with high environmental control needs for critical laboratories. We have worked with a variety of VAV/CV box controllers and have experience specifying and procuring BMS instrumentation. We also have significant experience using Rockwell PLCs for BAS, and we work with other leading vendors such as Aveva, Emerson, Inductive Automation, Schneider, Siemens, and more.

GAMP-Based Methodology

All of our projects are implemented following the InflexionPoint Methodology for Automation and Software. Based on GAMP, our approach ensures that systems are developed with the necessary planning, lifecycle documentation, and testing. Our methodology consists of a set of Quality Management Procedures that describe both Project Specific Validation Activities, as well as General Validation Activities. The project-specific activities of design, implementation, and testing follow a life-cycle development model, and general quality procedures govern activities such as document control, scheduling, training and internal auditing.

Contact

Have questions?

We have answers.

Do you have a Digital Transformation initiative? Need to upgrade your automation and controls systems? Wondering how you can become more data-driven? Let's talk.